The emergence of labeling machine greatly reduces the labor cost of enterprises and improves the work efficiency. A large number of products can be labeled with beautiful and clear labels. Do you want to know the working performance of the labeling machine? Next, Feituo automation technology will explain one by one:

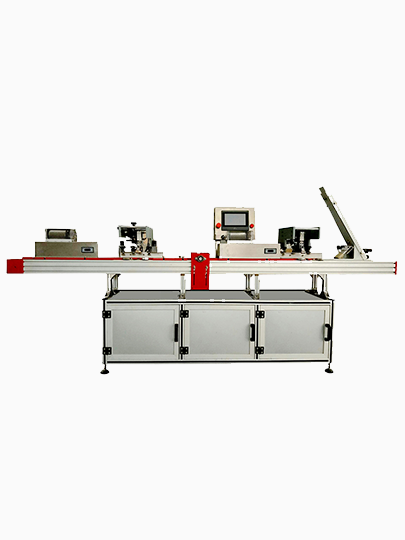

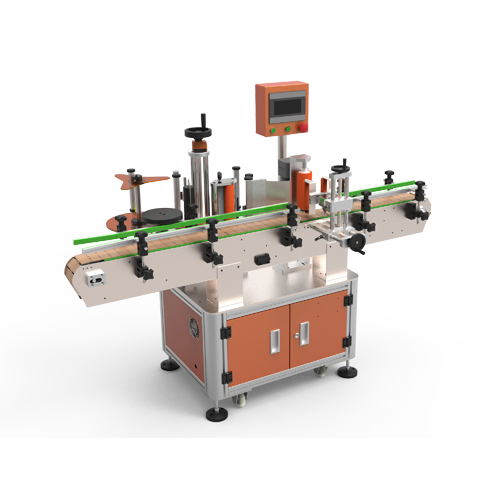

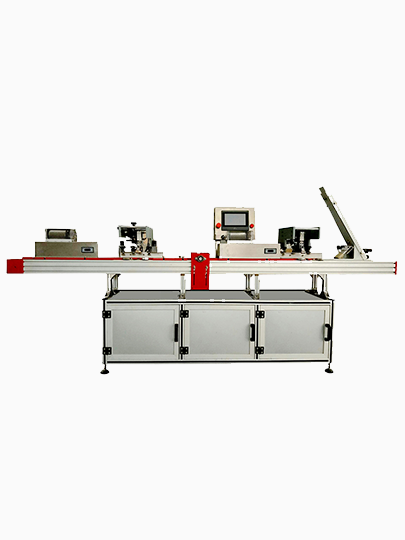

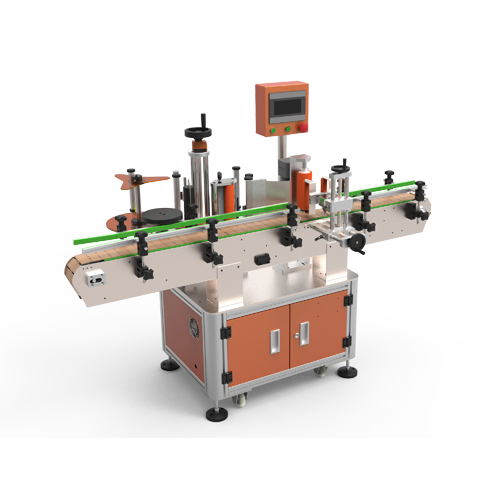

Labeling machine is divided into semi-automatic labeling machine and full-automatic labeling machine. It is applicable to the full circumference labeling of round cans, square cans, bottles, paper tubes and other cans with a diameter of 30-300mm and a height of 40-600mm. It can also be used to mark less than the entire circumference or less than the entire body. It is widely used in food. Mosquito and fly insecticides, air fresheners, self spray paint, swelling glue, butane gas, leather polish, etc. in beverage, pesticide chemical industry, paint and coating, medicine and health and other industries. The labeling machine is composed of industrial computer automatic control electrical system (Chinese and English interface), RTM servo motor, pneumatic components and color code detection system.

Labeling quality: the cut label pattern is complete without deformation; Always apply glue to the end net, saving 50% of hot-melt glue compared with foreign full spraying glue equipment; Correction ± 0.05 (mm); There is no heat shrinkage at the upper and lower openings; The overall labeling surface is smooth, and there is no dislocation, leakage and glue opening at the lap joint. For the product packaging industry, the labeling machine has played a certain role in promoting reform. Among them, semi-automatic labeling machine and automatic labeling machine are two types of machines with different degrees of automation during model selection and production.

Work steps: automatically complete all processes such as automatic introduction of tank body, label cutting, gluing, positioning, fitting, pressing, heat shrinkage, tightening of labels at the upper and lower openings of tank body, and 15- provide phase alarm system at one time. The working principle of the automatic labeling machine is basically like this. There may be some differences in some procedures between semi-automatic labeling machine and full-automatic labeling machine.

In the past, the domestic economic development model was "emphasizing the economy over the environment". With the deterioration of the surrounding environment, people began to pay attention to environmental protection. Packaging machinery manufacturers have made a series of adjustments for economic and environmental protection. In the automatic labeling machine industry, the company's product design features flexible and efficient, environmental protection and energy saving, convenient maintenance, mechanical automation and intelligent development.

Development characteristics of modern packaging equipment: first, strong flexibility. In order to meet the diversification of trial products, the same packaging machine is required to operate different products, such as automatic labeling machine, which is not limited to one product. Labels at the same location must also comply with different specifications. Labeling at different positions of the product to maximize the use of mechanical equipment. The secondary machine has high precision, high speed and high efficiency. The equipment is required not only to work stably at high speed, but also to ensure the output of products and produce the most products in the shortest time. Third, safe, energy-saving and environmental protection. In the production process of the equipment, the personal safety of users must be guaranteed to minimize the waste of energy. Finally, there is mechanical interconnection. In the process of equipment application, it is necessary to conveniently and quickly realize the connection between equipment and realize the communication between single machine or whole machine and monitoring system.

In addition, the modification and maintenance of mechanical equipment are also very important. If we can diagnose and repair some faults of the automatic labeling machine equipment, we can save manual operation and reduce maintenance cost to a great extent.